Start of magnetic measurements on Single Sheet Tester SST150 and the Epstein frame 700

ESIEE Amiens and the LTI (Innovative Technologies Laboratory) of the UPJV (University of Picardie Jules Verne) are in charge of magnetic and vibro-acoustic measurements on samples provided by partners with and without laser treatment.

The equipment allowing most of the macroscopic magnetic measurements arrived at the beginning of September at the laboratory of ESIEE Amiens. This equipment consists of a regulated 100V/26A peak power source allowing to generate any form of voltage or current with harmonics limited to the 20 kHz frequency (harmonic frequencies between 5 and 20kHz depending on the applications targeted by Jeumont and Sepsa) (see Figure 1). This source is programmed in such a way that it can always provide the current necessary to obtain either a controlled magnetic field on the surface of the samples or a controlled average induction in the section of the same sample.

The samples that can be characterized at ESIEE are either 30*280 mm rectangles or 150*150 mm squares. Square samples of 10*10 mm can be analyzed by MFM at the UPJV and measurements in rotating fields on 60*60 mm squares are subcontracted to the company BROCKHAUS (also a frame supplier).

In order to carry out the characterizations without any geometric effects to probe the intrinsic behaviour of a material, we use specific standardized frameworks (see Figure 2). Today, ESIEE has two types of framework. The first is an Epstein 700 frame (700 primary and secondary turns) dedicated to 30*280 mm samples that meets strict standards and requires the measurement of at least 4 samples and can accept up to 48 samples depending on its thickness. The second is a SST150 Single Sheet Tester that allows the magnetic measurement of one to four 150*150 mm samples or one to sixteen 30*280 mm samples. The advantage of this framework is that only one sample can be used to make the first characterizations, with a theoretically higher frequency limit than for the Epstein Bank.

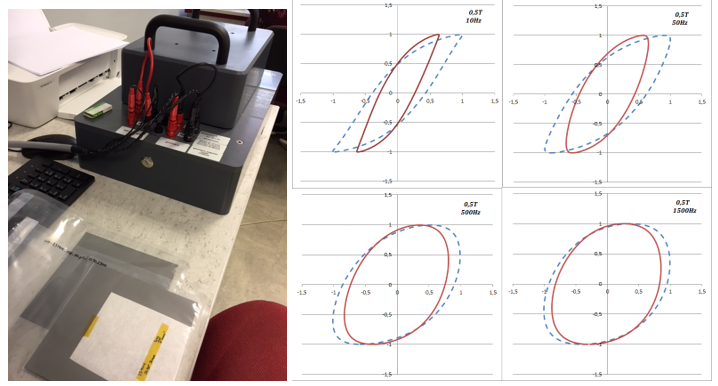

Figure 1: Regulated power source, Epstein and SST frames for magnetic measurements

After a short training period, the measurement campaigns began primarily on grain-oriented FeSi (GO) samples according to an experimental design agreed with ESIEE, MULTITEL and UPJV. Different laser parameters and therefore different types of surface treatment are studied. The purpose of magnetic measurements is to determine the main performances: static amplitude permeability, low-frequency magnetic losses called static losses, frequency losses called dynamic losses. These performances are studied according to the level of induction and saturation and its frequency of variation imposed in the material on the one hand and for several sets of laser parameters on the other hand.

First results obtained on GO FeSi samples with the SST framework show both an improvement in static amplitude permeability and a reduction in cycle surface area (i.e. total losses) for all induction levels and frequencies. On the other hand, this performance increase of more than 20%, moreover on two criteria, is all the more significant in absolute value because induction and frequency are important, and in relative value because induction and frequency are low (Figure 2). This result exceeds the expectations of the first objective of the project.

Figure 2: example of a 150*150 mm GO FeSi sample treated by laser with its cycle measured @0.5T @10, 50, 500 and 1500 (: without treatment and: with laser treatment). The field strength and induction values have been normalized to the maximum values obtained without laser treatment.