Work-packages

Technical Work-Packages

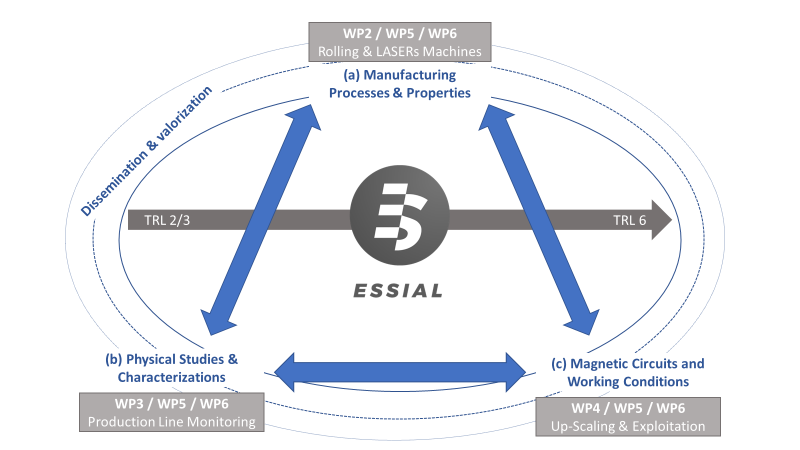

The concept of ESSIAL is based on the surface control, stimulation or induction of natural physical properties of magnetic materials, namely their tendency to organize in the form of magnetic domains and separating walls.

These tasks are covered in three Work Packages:

- WP2 will develop metallurgical and surface laser processes;

- WP3 will carry out numerous physical studies aiming at controlling and optimizing the surface magnetic structure in correlation with the manufacturing processes;

- And WP4 will consider the realistic use and working conditions of materials inside magnetic circuits of applications.

WP2: Manufacturing processes

Leader: MULTITEL

Participants: UniLaSalle Amiens, CRM group, IRT-M2P, UPJV, UC3M, ANDALTEC, Fraunhofer IPT, LASEA

Duration: M1 to M54

From the modelling and characterization point of view, the first goal of ESSIAL is to establish MANUFACTURING PROCESSES that will define the intrinsic mesoscopic properties (mesoscopic walls energy, anisotropy and exchange coefficients, dynamic damping, …) that can be associated to the main metallurgical properties of electrical steels:

- (a1) chemical composition (composition, electrical conductivity and mass density),

- (a2) crystallography and texture (axes direction onto the surface and in the bulk),

- (a3) metallography (grain size and shape, joint size and shape, …),

- (a4) bulk and surface geometry (sheet thickness, surface roughness, patterns of laser scribing, …).

This will be done in correlation with the metallurgical manufacturing process parameters (rolling stresses, heat treatment, cooling cycles, and mainly surface treatment).

WP3: physical studies

Leader: UniLaSalle Amiens

Participants: CRM group, IRT M2P, MULTITEL, UPJV, UC3M

Duration: M1 to M45

WP3 - PHYSICAL STUDIES -, consists in modelling and describing the macroscopic magnetic and magneto-mechanical behavior laws, including static and dynamic effects, scalar and vector contributions and surface coupling with the magnetic structure and the finite geometrical size.

General microscopic and mesoscopic models, with previously defined intrinsic parameters, will be proposed and developed. It will provide the following information for both material engineers (optimization of process parameters, focus on surface structuring process, and packaging) and machine designers (properties compatible with CAD and design tools):

- (b1) power losses and resulting heat flux (power loss Pf),

- (b2) magnetic permeability with non-linearity of magnetization and induced distortions (variable permeability m(B)),

- (b3) magnetic saturation curve, relaxation and aging phenomena (saturation polarization Bsat),

- (b4) damping and delay of magnetization (dynamic damping m(f or dtB)),

- (b5) magnetic hysteresis (Static and dynamic cycles (B, dtB), coercive force Hc, remanence Br…),

- (b6) induced internal stresses (magnetostriction, Maxwell stress),

- (b7) vibration and noise (vibration modes, acoustic noise magnitude).

The models should describe the magnetic structuring behavior depending on the material nature (its intrinsic mesoscopic properties) but also on the geometry, shape and typical size of the sample (sheet thickness and surface quality and texture). The models will also consider magnetocrystalline anisotropy, magnetic exchange, magneto-static or demagnetization, eddy currents damping, Zeeman and magneto-elastic energies due to the structuring process under steady state; and the dynamic reversal processes and microscopic eddy currents under transient and dynamic working conditions (namely Domain Wall Pinning (DWP), Bowing (DWB), Displacement (DWD), Fusion (DWF), Nucleation (DWN), Multiplication (DWM) and Domain Magnetization Rotation (DMR)).

WP4: Proof of concept

Leader: UniLaSalle Amiens

Participants: CRM group, IRT-M2P, MULTITEL, UPJV, UC3M, EREA, Jeumont Electric, ANDALTEC

Duration: M13 to M54

When WP2 and 3 are completed, we will need to know the typical surface magnetic structure, considered as a limit condition. The ambition of the project is to make the control of the surface magnetic structure possible. To this end, we will be able to build on the results of WP2 and 3 to develop OPTIMISED SAMPLES AND REDUCED SCALE MAGNETIC CIRCUITS, which will be measured and characterized in a relevant number of manufacturing and working conditions:

- (c1) module and direction of induction B vector,

- (c2) wave-shape and frequency of average induction,

- (c3) nature and geometry of samples,

- (c4) metallurgical process and heat treatment,

- (c5) surface treatment and patterns.

WP5: Prototypes

Leader: JEUMONT ELECTRIC

Participants: UniLaSalle Amiens, CRM Group, IRT-M2P, MULTITEL, UPJV, UC3M, EREA

Duration: M31 to M57

The following step will be to provide end users partners (JEUMONT and EREA) with optimized materials. Three prototypes, close to commercial products, will be manufactured and tested:

- A 355-kW rotating electrical machine (use of non-oriented or non-textured materials with larger thicknesses from 0.5 to 1 mm and for frequencies below 1 kHz)

- A 70-kVA voltage transformer associated to a power inverter (use of oriented or textured materials with thinner thicknesses from 0.1 to 0.6 mm with switching frequencies from 1 kHz to 3 kHz)

- One or two smoothing inductors dedicated to a DC/AC inverter (110 kVA) or an AC/DC LVPS charger (10 kW) (use of oriented or textured materials with thinner thicknesses from 0.1 to 0.6 mm with switching frequencies up to 3 kHz (5.5 kHz and 20 kHz))

WP6: Upscaling for mass production lines

Leader: LASEA

Participants: CRM Group, IRT-M2P, MULTITEL, EREA, Jeumont Electric, ANDALTEC, Fraunhofer IPT, LASEA

Duration: M10 to M57

In the fourth and last step (WP 6), the factory LASEA and the FRAUNHOFER-IPT will propose a complete definition of in-line monitoring and upscaling strategies for mass production.

Based on the metrology work achieved in the previous Work-Packages, an upscaling of the process will be designed by Fraunhofer IPT as far as the feedback control of the measured information is concerned. Fraunhofer IPT will develop in-line monitoring tools for the production process and the hereby manufactured surface geometries in two phases.

Starting at this point the process adaption will be done in tight cooperation with the machine integrator (LASEA) in order up-scale the technology for mass production

Support Work Packages

WP1: Management of the project

Leader: UniLaSalle Amiens

Participants: Euronovia

Duration: M1 to M57

This Work Package aims at managing the project in agreement with the EC rules, ensuring the quality of project reporting and organizing collaboration between the project partners, while monitoring the progress of the work plan.

WP7: Dissemination and exploitation of results

Leader: ANDALTEC

Participants: UniLaSalle Amiens, MULTITEL, UC3M, EURAMATERIALS, ANDALTEC, Fraunhofer IPT, Euronovia

Duration: M1 to M57

The main objective of WP7 is to identify the potential different routes for innovation and exploitation of the project results so as to maximize the project’s impact on the participating organizations and on the European industrial sector.

MATIKEM will carry out a search on scientific publications and patents, in order to keep the consortium informed of what is going on in the market. A valuable output of this technological watch activity will be the identification of European companies that could be interested in the ESSIAL innovation. Based on this identification of companies, a market study will be realized to estimate the volumes of production that will find customers in the actual European market.

Moreover, ANDALTEC will prepare a report on ESSIAL economic and environmental benefits of the ESSIAL products. This study will take into account the whole cradle-to-grave process of the developed products.

Finally, WP7 will disseminate the information about the ESSIAL project to a wide range of relevant stakeholders and to the public at large through various dissemination activities (such as conferences, workshops, newsletters, or a dedicated website).